2021 #CCEawards Showcase: Peter Lougheed Centre Temporary COVID-19 Treatment Facility

November 8, 2021

By CCE

“The engineering team was able to rise to the occasion under difficult, unprecedented circumstances and a very short timeline.” - Jury

Category: Buildings

Award of Excellence Winner: Stantec

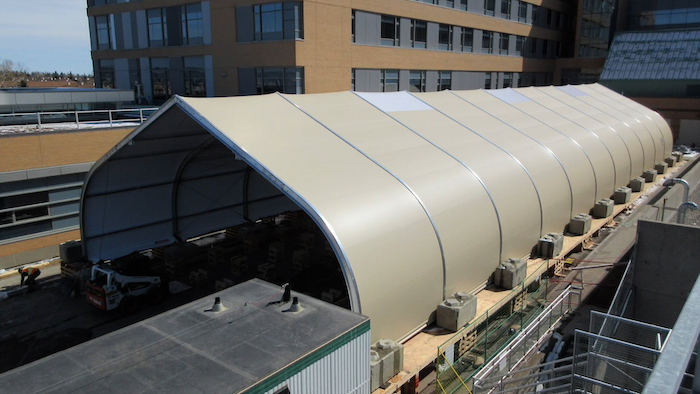

In March 2020, Calgary accounted for 63% of Alberta’s confirmed cases of COVID-19. Stantec, Alberta Health Services (AHS), Sprung Structures, Falkbuilt and CANA Construction worked together to build a temporary treatment facility at the Peter Lougheed Centre (PLC) to accommodate the predicted pandemic peak in May 2020.

Communication and co-ordination between all disciplines, physicians and nurses were critical. The more than 750-m2 pandemic response unit (PRU) was designed and entirely constructed in less than three weeks, providing an additional 70 treatment spaces for patients.

This project was a first for Stantec, AHS and the provincial government, due to its urgency. While it is a temporary structure, it operates much like a fully functioning hospital. And unlike other alternate care facilities (ACFs) built in convention centres during this pandemic, which only provide bed space, this project provided a fully functioning hospital unit, including medical gases, proper air exchange rates, nurse call and a direct connection to PLC’s emergency department.

Those building the structure wore N95 respiratory masks at all times and maintained physical distancing whenever possible.

Responding to immediate needs

At the time, the virus was not well-known and there was conflicting research. The World Health Organization (WHO) suggested it was transmitted by droplets only, while subsequent studies indicated the possibility of airborne transmission.

Stantec designed the ventilation system with airborne transmission in mind, configuring the airflow to travel from clean to dirty, with fresh air supplied near health-care workers and exhaust grilles near patients. The system was configured as a 100% outside-air system, with no recirculation, and used an upblast exhaust fan and high-plume stack to prevent entrapment of gases in the building.

The facility was designed to limit the spread of the virus within the hospital and to the surrounding community. Although physically connected to the main hospital, the PRU was negatively pressurized to prevent contaminated airflow from entering that structure.

Government predictive modelling projected the first wave would peak and then begin declining within three months, so the building was intended for very short-term use, but it could be easily winterized with insulation and heat tracing of all drains and water lines susceptible to freezing and air handling units with sufficient heat to operate in the winter.

As the pandemic proceeded and the facility was in fact required during the following winter, the structure was retrofitted with insulation to complete the winterization process.

Pandemic challenges

By April 2020, the entire province was in lockdown, with everything except essential services shut down. Nearly all construction projects were affected, with many put on hold.

Safe work protocols were still in development. Nobody knew which type of mask would best protect those physically involved in the project. There was a shortage of medical-grade N95 masks, but fabric masks could not be purchased in bulk. The decision was made for those building the structure to wear N95 respiratory masks (as used in dusty conditions) at all times and to maintain physical distancing whenever possible.

The project also ran into material supply challenges. Where possible, Stantec worked closely with contractors and suppliers to specify materials that were already in stock locally. Fortunately, all of these entities expedited their work to meet schedules. A local air handling unit manufacturer, for example, emptied its production line and was able to supply units in eight days, much faster than the typical 16 weeks.

Accelerated delivery

The speed of project delivery was unconventional. While there were additional costs associated with overtime and expediting delivery of building materials, these were offset by the cost savings of a significantly shortened schedule.

AHS provided consensus building and quick decision making. The proposed floor plan was signed off by clinical users in only two days, instead of the typical iterative process taking months.

This project demonstrated how strong project management, minimal red tape and quick decisions can lead to significant savings. Its model can be adapted to future projects.

Future use

The main benefit of a temporary facility such as this is it can be reused or repurposed for a variety of circumstances.

In the future, for example, PLC will renovate its emergency department. Stantec designed the temporary facility to be attached to this department for convenience of treatment, but also because it can be used as a decanting space when the renovations are underway.

After the facility is eventually dismantled, it can be redeployed at other AHS sites as decanting spaces or emergency shelters. Many components were specified for flexibility and reuse, including the air handling units, medical gas alarm systems and outlets, lights, medical equipment and movable partitions.

Peter Lougheed Centre Temporary Covid-19 Treatment Facility, Calgary, Alta.

Award-winning firm (prime consultant, structural engineer, mechanical engineer, electrical engineer): Stantec, Calgary (Jeff Rent, P.Eng.; Rory Smith, P.Eng.; Ronald Bonnett, C.E.T.).

Owner: Alberta Health Services.

Other key players: Stantec Architecture (architect), CANA Construction (contractor), Sprung Structures (fabricator).