Morrison Hershfield helps implement new rail maintenance technology in B.C.

July 14, 2022

By CCE

It's the first of its kind in Canada.

Consulting engineering firm Morrison Hershfield is working with Metro Vancouver’s TransLink and the British Columbia Rapid Transit Company (BCRTC) to implement a Hegenscheidt Mobiturn 2 mobile wheel lathe machine, the first of its kind in Canada.

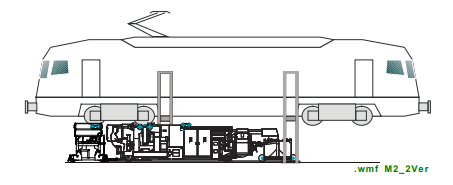

Developed in Germany, the Mobiturn 2 is reportedly the world’s first and only self-propelled wheel set maintenance machine that comes to the rail vehicle. It does not require a pit or foundation associated with a conventional underfloor wheel lathe installation. Instead, it travels within the railway maintenance facility, while transport lugs allow it to be loaded onto trucks for use at multiple facilities.

Vehicles requiring wheel profiling are elevated above the upper edge of the rail via in-floor hoist or portable lifts. The Mobiturn’s power supply cable is unwound as the machine moves by motorized traction drive under the wheel set to be machined, using radio control or a shunting vehicle. After the machine is positioned under the wheelset, it is raised with its own lifting mechanism to a working height to start the reprofiling.

The self-propelled wheel set maintenance machine comes to the rail vehicle, rather than the other way around. Image courtesy Morrison Hershfield.

TransLink and BCRTC have committed to implementing the equipment in two SkyTrain operations and maintenance centres (OMCs). Morrison Hershfield’s transit team is recommending power requirements and cable tensioning devices to accommodate smooth, uninterrupted machine travel and identifying appropriate clearance and design considerations for lifting and emptying wheel shavings from the machine hopper system.

By turning to alternative infrastructure, the project’s goals are to improve demand-oriented transit vehicle wheel maintenance, reduce rolling stock downtime, save money and improve efficiency. The mobile wheel lathe is designed for the machining of wheels, wheel sets and brake discs of rail vehicles on both installed and dismantled units.

Transit operators have used Mobiturn machines in other countries, including the Massachusetts Bay Transportation Authority (MBTA) in the U.S. This project will mark the technology’s second installation in North America.