Going Underground – Copeland Transformer Station

March 16, 2016

By Bronwen Parsons

The Copeland Transformer station in downtown Toronto is only the second station in Canada to be built underground. Adding to the project’s complexity, it is being constructed on the site of a historic railway Roundhouse.

Aerial view of Copeland Transformer construction site on edge of the Roundhouse in downtown Toronto. Caisson walls are under construction. Photo: Toronto Hydro/Arman Khabbazian

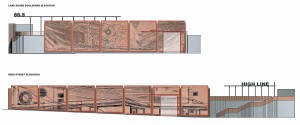

North-south section of the underground Copeland Transformer Station, Toronto.

From the January-February 2016 print edition, page. 19.

One of the last places you would expect to find a 5,000-m2 144-MVA transformer station is below a heritage building — least of all amid a cluster of tourist attractions.

Toronto Hydro is building the Copeland Transformer Station on excavated land at the historic John Street Roundhouse, deep in the business and entertainment core of Toronto. The Roundhouse sits on a park where huge steam engines are on display, and just to the north are the CN Tower, Rogers Centre stadium, Ripley’s Aquarium and the Metro Toronto Convention Centre. Along the southern edge are the main traffic arteries through the city: Lakeshore Boulevard and the elevated Gardiner Expressway, both roads crowded with vehicles at any time of day.

Most of the station is being excavated beside the roundhouse, but a portion of the structure lies directly below an ancillary building, the Machine Shop. In order to excavate for the new station, the historic brick and steel shop had to be completely disassembled piece by piece. Each component has been carefully logged, catalogued and stored until the structure can be rebuilt on top of the transformer station roof.

Shaun Pinard, P.Eng., who is in charge of the project for Toronto Hydro, explains that the 11,170-m2 machine shop will be reconstructed to meet current seismic standards. It will incorporate the original steel structure, but with reinforced concrete walls tied into the station structure below. The brick will be reinstalled on the walls as a facade. “The intention is that it will look and feel the same as the historic structure, but it’s going to be beefed up to be seismically compliant with the Ontario Building Code, as is the rest of the building,” says Pinard.

Why this site, and why bury it?

Dealing with the heritage buildings, numerous stakeholders, and the proximity of so much critical urban infrastructure made for a complicated approvals and construction process. The $195-million project was originally intended to be completed last year but it is still under construction.

Why choose such a difficult site? Toronto Hydro bought the land from Hydro One, explains Pinard, and “Based on the electrical load that has to be served, it is actually the best possible location that was available to us.”

Copeland Station is needed to keep the lights on in Toronto’s nearby financial district. It will also service the forest of condominium towers that have sprouted up in this downtown zone close to the lake. An existing nearby transformer station (Windsor) is due to be upgraded, so the Copeland station will fill in for it while also supplying new loads in the area. It adds 144 MVA of capacity to the network.

The decision to half bury the station avoids having an unsightly industrial plant above ground. The only other underground transformer station in Canada is the Cathedral station in downtown Vancouver.

“When you have to build a transformer station in a developed city like this one, it is very difficult to go the old route and build above ground like the 1950s Windsor Station up the street,” says Pinard. “It’s probably impossible to get the approvals to do something like that in a city. People want something that fits in better.”

In another concession to the busy context, the transformers will be insulated with non-flammable SF6 gas rather than the conventional insulator, oil. The use of gas insulation is rare in North America and more expensive, but it means there is “very little, if any, risk of a fire or explosion,” says Pinard. The cost is offset by not having to use sophisticated fire protection systems.

An irregular roof

The station is 12 metres below ground at its southern edge, but due to the rising elevation, sits at grade at Bremner Boulevard on the north. The switchgear and the transformer, which converts incoming high-voltage 115 kV power to 13.8 kV medium-voltage power for distribution, will be installed in the first level below ground. The transformer is huge — 16 x 10 x 6.6 metres, and weighing approximately 220 tons when it’s assembled. The critical control equipment will be above ground, housed in the reconstructed Switching Shop. The basement level will hold all the equipment connections and power cables.

How to insert the large transformer equipment inside the building — which should happen by late February — was just one of the engineering challenges facing IBI Group, the prime consultants.

Alexandre Haddad, P.Eng., project director for IBI, explains their solution: “Our engineering team came up with a roof opening that has precast panels that can be removed. The station transformers will be installed through that space and rolled inside.”

The roof spans between 50 and 100 metres. It has to support the weight of the rebuilt Machine Shop, as well as a driveway that carries heavy trucks. One of the tenants in the Roundhouse is a brewery. “Steamwhistle uses full size water tankers to bring water into their facility so we had to design the roof of the station similar to a bridge with a building on top,” Haddad explains. In the area of this driveway the roof consists of a 450-mm thick reinforced concrete slab supported by large reinforced concrete beams and girders. The girders span up to approximately 20 metres and are up to 1.8 metres wide and 2.6 metres deep.

The building’s irregular form curves to match the Roundhouse on one side and has “all kinds of shapes in one floor plate to fit the available property,” says Haddad. Once the station roof construction and the Machine Shop are complete, the remaining portions of the roof will be covered with landscaping.

Keeping dry

Perhaps the biggest engineering feat is keeping water out of the building. Water and electrical equipment don’t mix, but this underground vault sits on infilled land south of Toronto’s original shoreline. The water table is high.

The solution is a “bathtub” design whereby the caisson shoring wall has been left in place. This wall is lined on the inside with a waterproofing membrane of high-density polyethylene. Inside the liner are 800-mm thick heavily reinforced concrete walls. The concrete has a special waterproofing admixture. On the floor is a 1.35-metres thick reinforced concrete mat, which is anchored into the bedrock below to resist buoyancy forces.

As an added precaution in case any water does enter, there are two sets of sump pumps. These have emergency power supplied from off site.

The cable tunnel

A new cable tunnel has been built to connect with an existing Hydro One cable tunnel along Front Street to the north. MMM Group designed the tunnel, which begins with shafts below the transformation station, then extends north 600 metres below Lower Simcoe Street.

Again, dense development in the vicinity caused complications. Alex Williams, P.Eng., project manager at MMM, explains that there was no space on Front Street to build an exit tunnel for the tunnel boring machine, so the TBM had to be backed out when it finished its work. It was also difficult to find locations for the ventilation tunnels.

Even below ground there were difficult encounters. “Normally at a depth of 35 metres there are no conflicts with existing infrastructure,” says Williams. “In this case we had to stay clear of the Metro Toronto Convention Centre’s underground parking structure, the existing Enwave tunnel [part of a district deep lake water cooling system], and a city watermain.”

The 3.5-m diameter tunnel is lined with 280-mm concrete. It is ventilated and carries two circuits, which are separated using concrete encased ducts.

Taken together the tasks of fitting the station into the complex urban fabric makes for a unique and interesting project. Besides all the engineering design issues, there are the logistical problems of constructing such a huge project in a crowded area. Construction crews and delivery trucks have to deal with not just the regular heavy traffic, but also major sports and entertainment events held nearby. These included the PanAm Games held in the summer of 2015.cce

Copeland Transformer Station Team

Owner: Toronto Hydro

Transformer station IBI Group (Alexandre Haddad, P.Eng., Nicolas Al-Nakhl, M.Eng.,

prime consultant, Divinia Santiago, Roman Kucharczyk, Ray Krawchuk, Justin

architecture/ Wuohela, P.Eng., Barry Medford, P.Eng., Raymond Wong,

engineering: P.Eng., Piero Lucci, P.Eng., Trevor McIntyre, Don Loucks, Karl Isomaki)

Tunnel prime MMM Group

consultant: (Alex Williams, P.Eng.)

Contractors: Carillion, Dibco, Arno