Brought to you by Victaulic

Costly engineering mistakes to avoid in your high-rise riser system

December 15, 2023 in Engineering

By Robert Johnson, P.E.

Photo Credit: Victaulic

Photo Credit: VictaulicIt’s common to have dual-temperature fan coil units specified for every suite of a condominium or other high-rise building to improve temperature and humidity control for occupants. This construction trend means engineers must account for dozens of hydronic risers when designing a vertical system — any of which could cause millions of dollars in damages and repair costs if they fail.

Engineers must balance numerous factors to ensure the reliability and longevity of increasingly complex HVAC systems. When analyzing why systems commonly fail, we find there are two critical areas where designs often fall short.

Issue #1: Poor anchor load distribution with in-line expansion joints

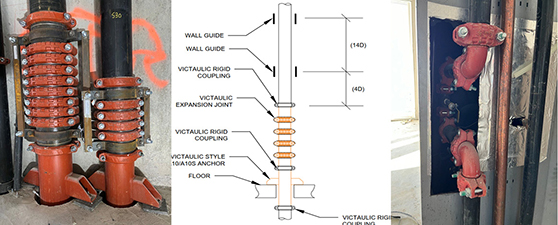

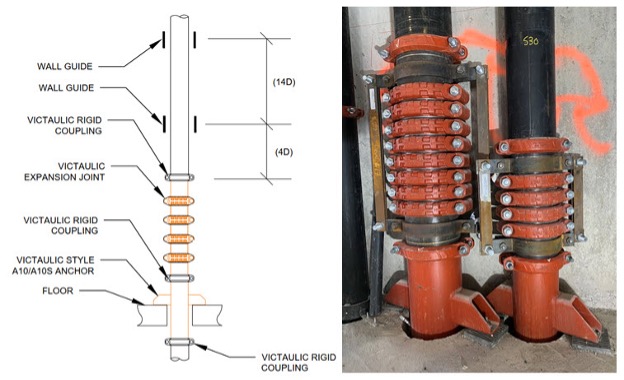

Expansion joints absorb the thermal movement that pipes experience as changing water temperatures cause expansion and contraction. Anchors and guides must then be used to restrict pipe movement and control the pressure thrust forces created by the expansion joint, which is intensified by gravity in vertical risers. As a rule of thumb, you need two anchors for every expansion joint (n+1). Since the building structure will support each anchor, engineers must pay particular attention to the expansion joint and anchor location to attain an ideal load distribution.

Placing an expansion joint too high decreases the load on Anchor A and increases the load on Anchor B, which is located at a lower elevation. This adds stress to the supporting structure. Engineers often do this to compensate for an expansion joint product with low-pressure parameters.

However, Victaulic engineers developed a solution to address the issue and preserve the integrity of the system and structure, focusing on strategic expansion joint placement. This is accomplished by moving the expansion joint location away from Anchor A and closer to Anchor B increases the pressure that the expansion joint experiences (within acceptable parameters) while decreasing anchor load on the building structure. With this method, Anchor A is responsible for supporting the majority of the pipe weight while Anchor B supports the majority of the water weight, thereby optimizing the anchor load distribution on the structure.

Photo Credit: Victaulic

Issue #2: Expansion loop misalignment

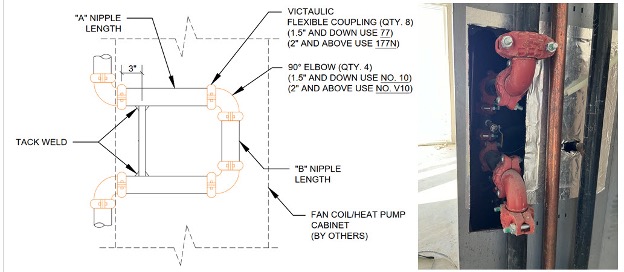

Expansion loops help relieve stress on the piping system, adding space for thermal movement while reducing anchor load demand. Expansion loops in fan coil riser systems can be extremely sensitive to misalignment and pressures, especially in welded steel or soldered copper systems. In these cases, the contractor must guide incoming pipe on the top and bottom sides of the loop to keep pipes straight. Loops fail when pipes become misaligned, typically breaking at the hose section because of twisting or overloading.

Engineers can mitigate misalignment risk by using Victaulic grooved technology and engineered solutions. The grooved solution applies a similar geometry but substitutes welded connections with flexible couplings and elbows, providing better angular deflection at a similar footprint. Beyond improving system flexibility, grooved loops streamline maintenance for end-users since they don’t require a maintenance schedule to confirm joint integrity.

Photo Credit: Victaulic

Conclusion

The taller the building, the more demanding its riser system design becomes. Victaulic solutions have evolved to adapt to these changing system requirements and are presently employed in some of Canada’s tallest structures, including a 105-story Toronto skyscraper. When engineers embrace innovative construction solutions that eliminate historical challenges that lead to costly system failures, it empowers owners and developers to fully utilize the ample vertical real estate within their reach.

About the author

Robert Johnson, P.E., has more than 12 years of mechanical and piping engineering experience in high-rise, oil & gas, mining, nuclear power, and water treatment sectors. He is a Piping Movement Design Supervisor at Victaulic, a global producer of pipe-joining, flow control and fire protection solutions for the most complex applications. Since 1919, Victaulic’s innovative solutions and design services have helped increase construction productivity and reduce risk, ensuring projects are completed safely, on time and within budget across 120 countries. Learn more at www.victaulic.com.