Wire processing at speeds ten times faster than by hand

September 5, 2023

By

Canadian Consulting Engineer

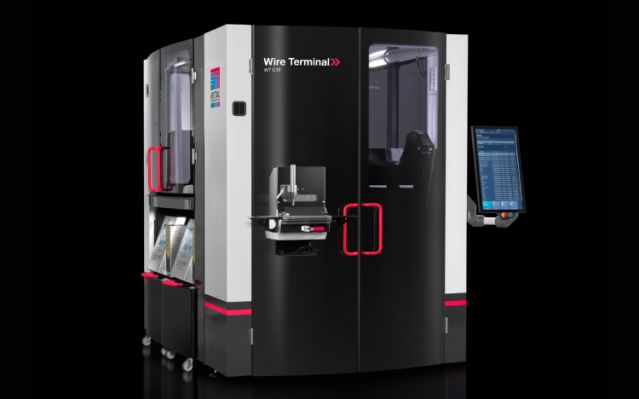

Wiring in panel building and switchgear manufacturing are time-consuming elements, taking up around 50 per cent of the processing time. Rittal has introduced its Wire Terminal WT C5 and C10 innovations that allow wires with individual wire printing (black, white and light blue) and picking to be assembled ten times faster than by hand.

The Wire Terminal WT is available in two different versions and flexible configuration stages. As an entry-level wire processing solution, Rittal offers the WT C5 variant with five vibratory bowl feeders for wire-end ferrules and a wire-end treatment feature for wires with cross-sections ranging from 0.5 to 2.5 mm². The product also cuts to length, labels and crimps. The WT C10 variant has ten vibratory bowl feeders for wire-end ferrules with wire cross-sections of up to 6 mm² as default. Both variants allow further expansion to full functionality in the respective wire application.

The fully automated machine, easily operated via a 24″ display, offers many improvements and innovations, such as when feeding and outputting the wires. Safe wire feeding and a simple, fast changeover to other wires are achieved via a new type of wire feeding system featuring three feed blocks for as many as 36 wires and with 12 wire types per feed block. The quick-change system allows the feed blocks to be set up and changed flexibly. An RFID transponder automatically secures the wire feed. This makes it easy to change complete wire magazines.