Motion Terminal VTEM uses digital pneumatics

January 27, 2021

By CCE

The system combines hardware and software.

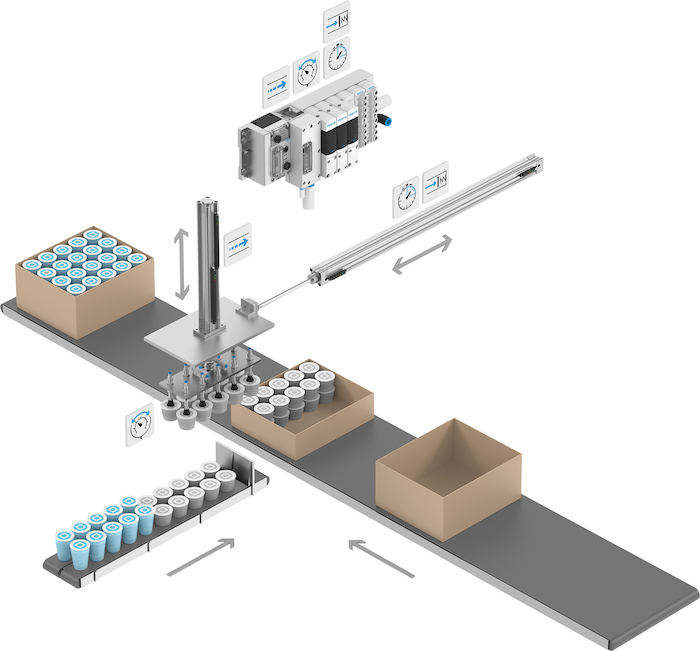

Festo’s Motion Terminal VTEM uses digital pneumatics to help engineers upgrade common automation processes, like machining, parts handling and assembly, pick-and-place and dosing, among others.

More precise and flexible than standard pneumatics, VTEM uses 11 motion software apps for fast changeovers between different sizes or shapes of workpieces, products or packaging, completing adjustments in minutes that used to take hours. Piezoelectric valve technology within the motion terminal prevents the need for up to 50 downstream components, such as sensors, regulators, flow control valves and shock absorbers.

The motion apps establish parameters for such functions as proportional and directional valve control, proportional pressure control and selectable pressure levels, positioning, supply and exhaust air flow control, soft stop, energy optimization and leakage diagnostics. The piezo valves can be used both as proportional valves and as control valves. Thus, the overall system is a reprogrammable combination of hardware and software, adaptable to each relevant application.