Modular cooling tower for industrial plants

December 11, 2017

By

CCE

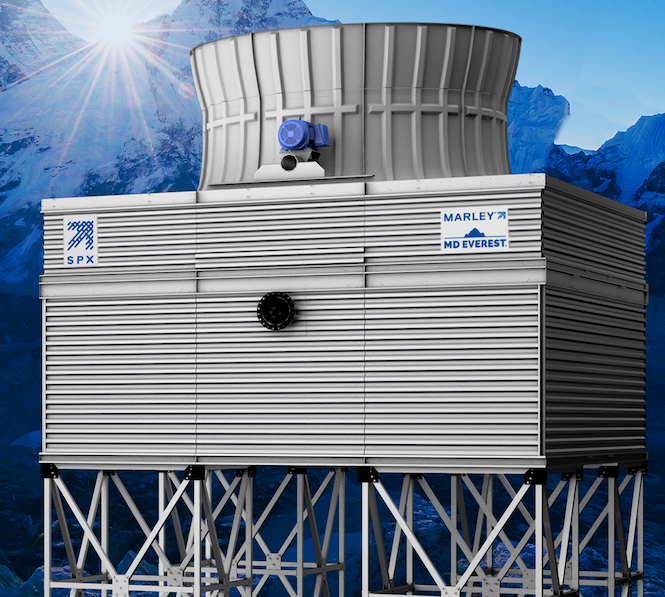

The Marley MD Everest counterflow tower’s structure meets seismic and wind load requirements per ASCE and IBC building codes.

SPX Cooling Technologies manufacturer of evaporative and air-cooled heat exchangers, has introduced the new Marley MD Everest, a modular counterflow cooling tower.

SPX Cooling Technologies manufacturer of evaporative and air-cooled heat exchangers, has introduced the new Marley MD Everest, a modular counterflow cooling tower.

The MD Everest cooling tower is designed to meet process cooling demands and is suitable for power generation plants, chemical, oil and gas plants, and other process applications with a wide range of thermal loads.

Whether designing a new plant or replacing an aging traditional site-constructed cooling tower, the MD Everest tower’s pre-configured design offers significant advantages that enable safer assembly processes, including up to 60% faster delivery and 80% faster installation compared to field-erected cooling towers.

The Marley MD Everest counterflow tower’s structure meets seismic and wind load requirements per ASCE and IBC building codes, and withstands the rigours of process cooling applications using heavy-duty, corrosion-resistant materials. Industrial-strength Marley mechanical components include a System 5 Marley Geareducer gear drive; energy-efficient, low-clog PVC heat exchange fill media; and Motor Outside Airstream (MOA), standard. The MD Everest also includes a five-year mechanical component warranty.

MD Everest cooling tower is delivered in modules to facilitate efficient installation. Its thermal performance is pending certification by the Cooling Technology Institute (CTI), eliminating the need and expense for on-site testing.