Parametric thermal bridging analysis

August 13, 2021

By Scott Armstrong

TEDI provides focus for enclosure performance improvements.

As “per cent better than code” is a fading metric, the construction industry has seen the rise of a new performance paradigm: thermal energy demand intensity (TEDI). Simply defined, TEDI is the measure of heating energy required to offset enclosure losses and to heat fresh ventilation air. Thus, enclosure performance is no longer subject to trade-offs with highly efficient mechanical systems. Indeed, it’s paramount to achieving success.

TEDI has been adopted as a compliance metric for the Canada Green Building Council’s (CaGBC’s) Zero Carbon Building (ZCB) program and the Toronto Green Standard (TGS). It has also been a requirement of Passive House projects since that certification’s inception. Coupled with requirements to incorporate thermal bridging into whole-building performance values, TEDI is changing the way consulting engineers design and construct buildings.

Design strategies and performance

There is increasing awareness in the design and construction community of the importance of achieving a thermally efficient building enclosure, with some provinces and municipalities referencing Passive House or the CaGBC ZCB standard. These programs include performance-based targets for three primary metrics: TEDI, total energy use intensity (TEUI) and greenhouse gas intensity (GHGI). Building enclosure performance influences each of these metrics, but is often most noticeable through TEDI.

TEDI accounts for the energy required to offset enclosure gains and losses and to temper ventilation air. Spaces requiring high ventilation rates, such as laboratories and hospitals, can overwhelm enclosure-related TEDI measures, but these types of buildings still benefit from thermally efficient enclosures by improving their resilience to alternate uses, ensuring passive survivability, improving occupant comfort and enabling low-energy mechanical HVAC systems.

Low-energy HVAC systems also support fuel switching, which can significantly reduce a project’s operational carbon emissions.

There is increasing awareness in the design and construction community of the importance of achieving a thermally efficient building enclosure. Photo by Andrea Yee, courtesy WSP.

Solar heat gain

TEDI can be improved (i.e. reduced) by including higher solar heat gain glazing balanced with fixed or dynamic shading. This approach helps maximize passive solar gains in the winter, then reduces solar gain and overheating in summer.

These strategies should be refined following a more detailed solar study for a proposed design, but some options (applicable within Ontario’s Golden Horseshoe) include:

- higher solar gain with dynamic or fixed shading on the south elevation to control overheating.

- lower solar heat gain or dynamic glazing systems on the east and west elevations.

- higher solar gain on the north elevation without shading.

Wellness-oriented spaces, like eateries, activity rooms, gyms and meditation/yoga rooms, could also benefit from larger windows and associated views, daylight and passive solar heating. Hallways with larger glazed areas could also be considered along the south façade as a buffer for open or closed offices, benefiting from controlled solar heat gain in the winter.

Glare issues from large spans of glazing can be mitigated by using lower visible light transmittance, dynamic glazing, diffuse glazing or creative shading strategies. Consideration could also be given for ‘cascading’ conditioning of different spaces or redistribution of energy between compatible spaces.

Spaces like gyms could benefit from larger windows.

It is important to understand the solar exposure for each site and the effect of geographic location, building orientation, building form and adjacent/ overshadowing conditions. These unique aspects for each site could also inform the façade design, by incorporating bespoke shading solutions. One example would be a custom exterior shade profile that traces the line of highest largest solar gain, giving architectural expression to climate adaptation.

Highly glazed façade assemblies must be thermally efficient to avoid offsetting passive heating benefits. Passive solar benefits can be achieved with modest glazing ratios and by balancing the highly glazed façades with opaque walls.

Adding more insulation will not necessarily result in dramatically more efficient assemblies.

Thermal bridging effects

Thermal bridging occurs when heat flow bypasses insulated building enclosure elements through highly conductive materials, reducing the overall effective thermal value of the enclosure and creating uncomfortable living conditions for occupants.

Most energy analyses account for thermal bridging only through clear field wall assemblies (e.g. cladding attachments) and standard National Fenestration Rating Council (NFRC) window assemblies. However, programs like the National Energy Code for Buildings (NECB) 2015, TGS, Passive House and CaGBC’s ZCB require teams to account for other regular and irregular thermal bridging, including:

- linear conditions (projecting concrete floor slabs, parapets, masonry shelf angles, window-to-wall transitions and building corners).

- point conditions (structural penetrations, shade supports and roof anchors).

There is growing demand for detailed analyses that include these elements. As designers, it is important for consulting engineers to use the same terminology when discussing an enclosure’s thermal performance.

Apart from providing accurate input data for energy modelling, a thermal bridging analysis can provide direction for improving the thermal performance of the building envelope through small design modifications.

Experience shows the thermal bridging effect of standard practice detailing can reduce the actual performance of a clear field thermal value by upward of 50%. The reduction is more pronounced for higher clear field thermal values.

Adding more insulation will not necessarily result in dramatically more efficient assemblies. It is essential to address the thermal bridge. Conducting a parametric or sensitivity analysis of thermal bridging conditions can help determine where detail updates may produce the most benefit to a given project. The following are some examples:

- Adding a thermal break can help to mitigate heat loss through the slab.

- Continuous insulation layers should be ensured at junctions, such as corners, parapets and wall type transitions.

- Bridging elements on the exterior, such as structural penetrations, should be insulated.

This level of analysis has led to discussions of omitting a second energy recovery ventilator (ERV) in a residential suite, eliminating perimeter heating in commercial buildings or targetinga higher tier as per TGS (i.e. Tier 2 instead of Tier 1). This flips the script on traditional discussions about whether enclosure upgrades are worth doing at all.

Making improvements

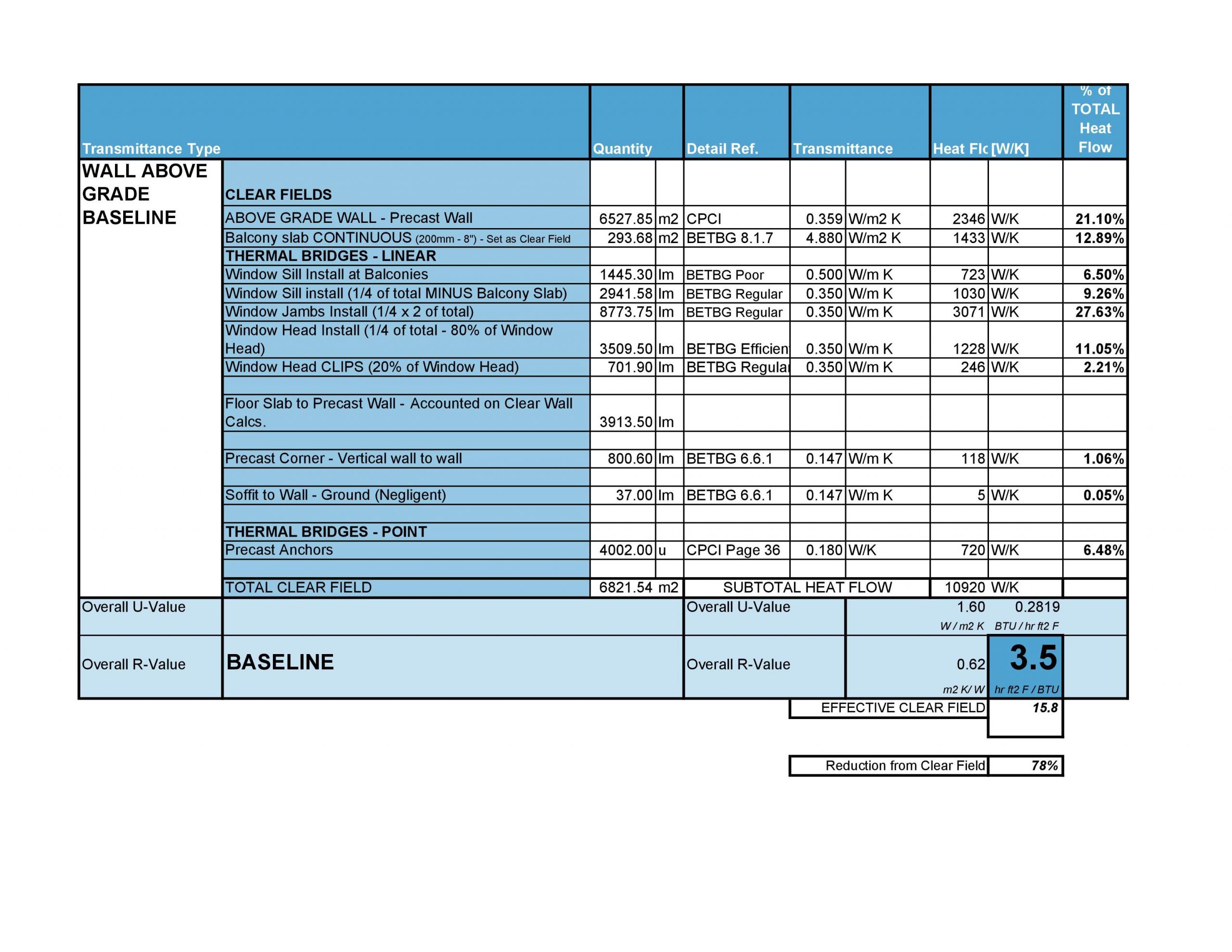

Chart 1 provides an overview of the thermal bridging analysis for a typical mid-rise multi-unit residential building (MURB) in Toronto, focusing on above-grade opaque wall assemblies. The assembly for this project includes a precast cladding panel with an effective R-16 clear field thermal value.

Factoring in the thermal bridging from panel anchors, building corners, balcony slabs and window perimeters, the clear-field R-16 is reduced to a whole-wall R-3.5. That is a 78% reduction in thermal performance!

The following are a few of the key findings of the analysis:

- Insulated precast panels, comprising 96% of the total surface area of the opaque enclosure, account for only 21% of total heat flow.

- Precast anchors account for approximately 6.5% of total heat flow.

- Balcony slabs account for nearly 13% of total heat flow.

- Window perimeters account for nearly 57% of total heat flow.

- Building corners and soffit interfaces account for slightly more than 1% of total heat flow.

This data helps steer attention to the detail that most significantly influences thermal performance in this building: the window perimeter.

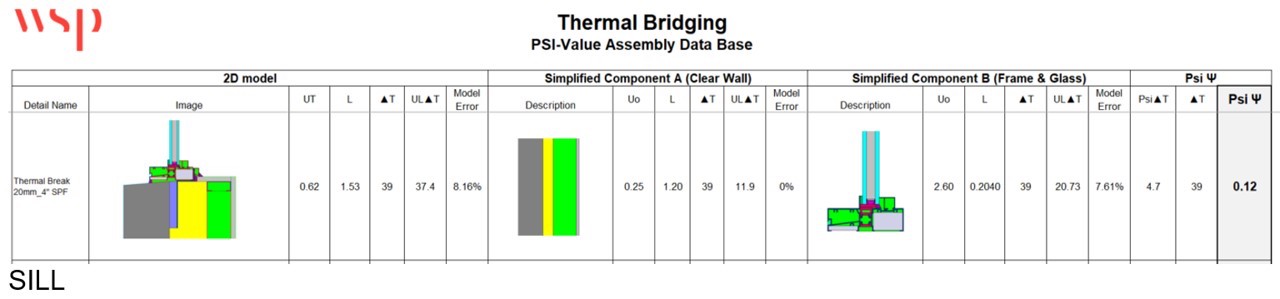

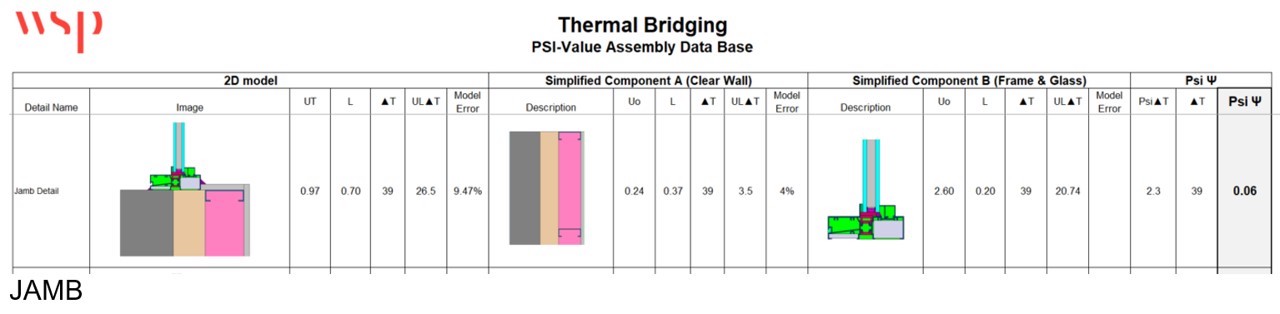

Using thermal modelling software, it is possible to make improvements to the details and calculate project-specific linear transmittance (PSI or ψ) values for the window-to-wall interface detail or point transmittance (CHI or χ) values for penetrations.

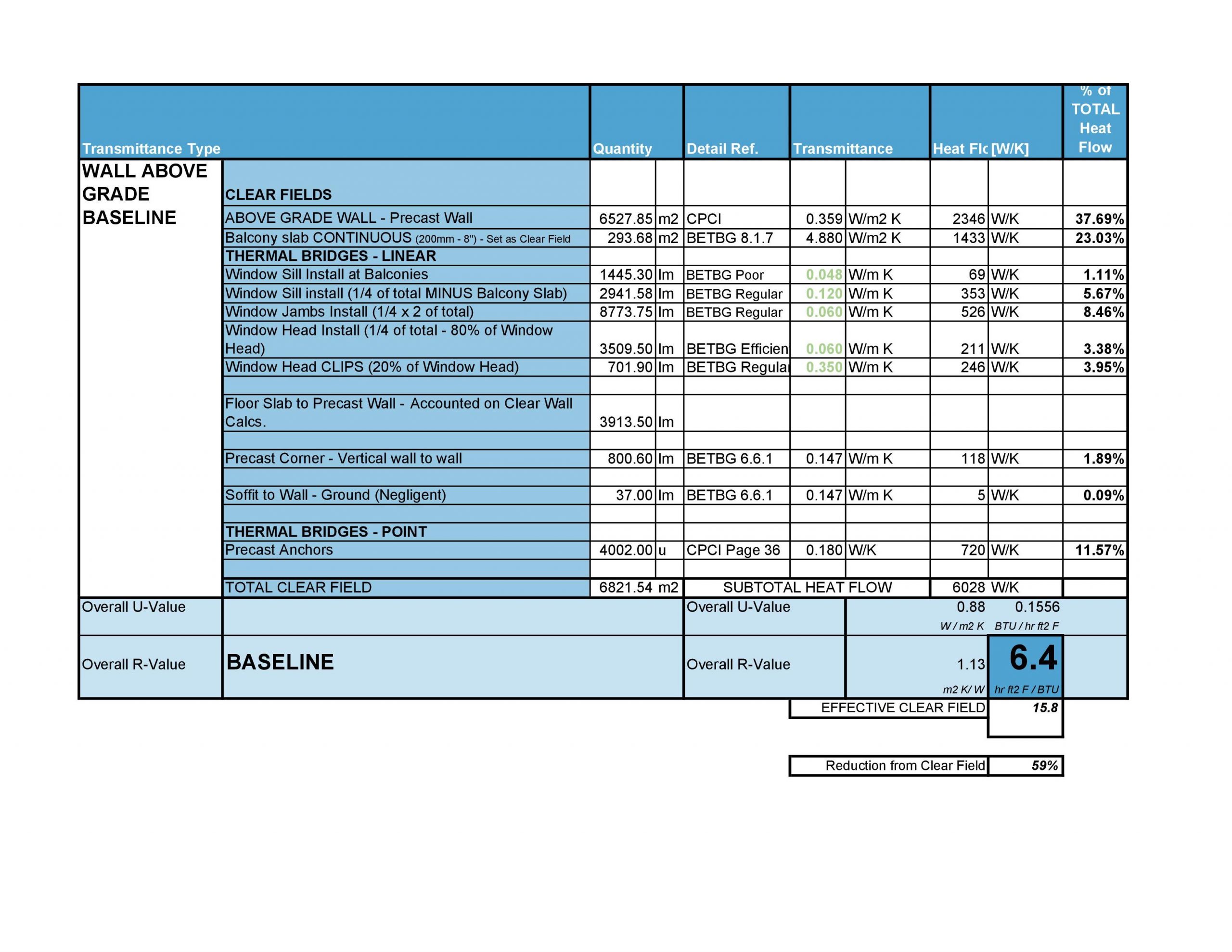

Charts 2 and 3 illustrate the process for determining custom linear transmittance values for project-specific conditions. Based on this data, the ψ value for the window perimeter can be reduced from 0.35 W/m K to 0.06 W/m K for the jamb and head and 0.12 W/m K for the sill. Substituting these values into the thermal bridging analysis demonstrates the influence of adding a thermal break at the window anchor and corresponding improvement in whole-wall thermal value; see Chart 4.

This single detail improvement results in a near doubling of the total wall R-value! This is the power of parametric thermal bridging analysis.

It is possible to parameterize specific elements in this analysis in a computation design workflow, including materials within the details and the thermal modelling process itself. Doing so could reduce the time needed for custom modelling, particularly in the early design stages when fewer details are available.

The time is right

Low-energy, low-carbon buildings demand thermally efficient building enclosures. Analyzing these buildings using energy modelling tools requires accurate metrics for their enclosures’ thermal performance.

Performing a parametric analysis of thermal bridging conditions allows design and construction teams to understand the effects of seemingly minor details on the overall thermal value. This process also helps teams manage critical decisions regarding enclosure design, adding thermal breaks where needed to optimize performance.

As code and local jurisdictions introduce requirements for detailed thermal bridging analysis, the time is right to incorporate this process into more projects.

Scott Armstrong is a senior façade specialist with WSP in Canada. For more information, contact him at scott.r.armstrong@wsp.com.

This article originally appeared in the July/August 2021 issue of Canadian Consulting Engineer.