Sheridan College’s District Energy Plant

December 14, 2017

By Victaulic Communications with files from CCE

Professional piping services assist in completing fast-tracked project schedule.

From the December 2017 print issue of Canadian Consulting Engineer, p. 16

Sheridan College invested $47.5 million to construct a new, state-of-the-art learning facility dedicated to skilled trades at its Davis Campus in Brampton, Ontario.

Sheridan College invested $47.5 million to construct a new, state-of-the-art learning facility dedicated to skilled trades at its Davis Campus in Brampton, Ontario.

The three-storey, 130,000 sq. ft. Skilled Trades Centre encompasses 22 flexible classrooms, a learning commons, and 52,000 sq. ft of space dedicated to workshops for plumbing, electrical, machining, industrial millwright, welding and construction programs.

Designed by George Friedman Architect, the building is designed to reveal its inner workings including structure, mechanical ducts, plumbing, electrical conduit and IT cabling.

“The design echoes what will be going on inside it—it’s a ‘tough’ building,” said George Friedman in a media release July, 2015 when construction was beginning. “The design hearkens back to the factories of the industrial revolution, in which structures were exposed and formed the architectural expression, while also meeting the sustainability requirements of modern architecture.”

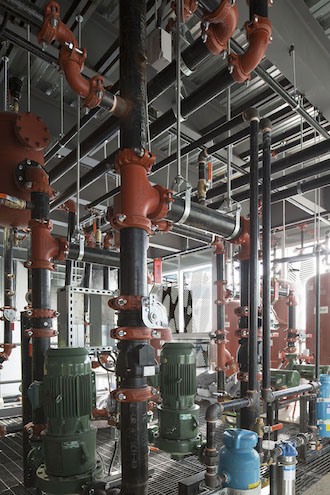

Sustainable solutions in the new building include rainwater collection systems, LED lighting, a photovoltaic rooftop system and skylights. Notably, the facility also operates its own district energy centre which contains seven different hydronic systems that provide the heating and cooling network for the campus. The Energy Centre, a living lab for the students with glass walls and energy-use metrics on display, also includes combined-heat-and-power generation.

Absorption chillers will utilize waste heat from the co-gen equipment to provide cooling along with conventional chillers. The building’s classrooms and labs will be heated with high-efficiency HVAC equipment that includes in-floor radiant heating/cooling with overhead chilled beams providing ventilation air via dedicated makeup air units.

Following the ground breaking in spring 2015, the school opened in January 2017, welcoming students for their first semester in the new building, but it wasn’t without a few hurdles along the way.

Insight Engineering & Construction, the project mechanical contractor, was tasked with designing and installing four separate heating systems by November 2016—ahead of the frigid winter temperatures.

In addition to the compressed timeline, space was at a premium. The district energy center needed to be built within a reduced footprint to leave room for the glass enclosure and student viewing areas.

In addition to the compressed timeline, space was at a premium. The district energy center needed to be built within a reduced footprint to leave room for the glass enclosure and student viewing areas.

To ensure the hydronic components would fit and installation maneuvers could be made in the tight space, the piping had to be designed, pre-fabricated and installed in a specific sequence.

With the deadline approaching and a challenging work environment ahead of them, Insight needed a solution to help overcome the design and installation challenges. Insight engaged Victaulic’s construction piping services (CPS) to layout the equipment and design the piping system drawings for pre-fabrication to help boost productivity and save time in the field.

“The Insight team needed the construction piping drawings expedited, but didn’t want to sacrifice quality or safety,” said Victaulic’s CPS team, “so we discussed many deliverable options and how Victaulic could best assist their design and schedule requirements.”

Together Insight and Victaulic came up with a unique sequence for installing the priority piping systems while meeting the project’s needs. This included setting up their own onsite fab shop to minimize lead time between receiving the drawings and installing the fabricated spools.

Insight also used Victaulic’s installation-ready couplings, valves, fittings and Koil-Kits on the chilled beams and terminal coil hook ups. The preassembled coil hookup kits allowed for a fast and easy installation which translated into overall time savings.

Insight also used Victaulic’s installation-ready couplings, valves, fittings and Koil-Kits on the chilled beams and terminal coil hook ups. The preassembled coil hookup kits allowed for a fast and easy installation which translated into overall time savings.

Victaulic’s CPS team and grooved solutions helped Insight fabricate, install and start up the district energy center’s heating system ahead of schedule so students could occupy the new wing in the upcoming semester.

“It made sense to go with Victaulic,” said Adam Roznicki, piping supervisor, Insight Engineering & Construction. “We were already using their couplings and fittings but their CPS solution helped facilitate the tight timeline and intricate layout of the facility.”

Roznicki said the CPS team was very hands on and collaborative, advising them on efficient piping layouts and providing a complete set of isometric drawings and 3D models that outlined a clear, simple and successful direction for the installation project.

Importantly, Roznicki explained that Victaulic’s CPS team proved an invaluable asset in consultation with the contractors, who foresaw the need for additional resources due to the approaching winter weather and tight deadline.

“This wasn’t the first time we used Victaulic’s construction piping services,” Roznicki said. “We always had great experiences—they deliver on time, and everyone is willing to help and ensure all the information is provided to get the job done safely and efficiently.”

Insight Engineering & Construction and Victaulic came together for the efficient completion of the new district energy centre and completed the project in time for the new semester.

Skilled Trades Centre, Energy Centre, Brampton, Ontario

- Owner: Sheridan College

- Architect: George Friedman Architect

- Mechanical engineer: The Aquila Group

- Mechanical contractor: Insight Engineering & Construction

- Contractor: Giffels Constructors