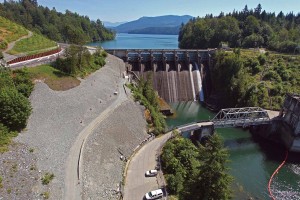

Award of Excellence: Ruskin Dam, Right Abutment Seepage Control Upgrade

October 24, 2015

By Golder Associates

“This was a challenging rehabilitation of a 1930s dam in Mission, B.C. It had suffered seepage issues that compromised its integrity. To address the problem the engineers basically had to cut a 25 metre deep slot in the existing dam and seal it with a mastic asphalt membrane. It required precise drilling techniques in challenging site conditions.” – Jury

From the October-November print edition, p. 53

Ruskin Dam, Right Abutment Seepage Control Upgrade, Mission, B.C. Photo: Golder Associates.

Since the reservoir was filled 85 years ago upon completion of BC Hydro’s Ruskin Dam near Mission, B.C., seepage has occurred from the right abutment. The abutment was founded on dense, highly erodible sands. Over time, the seepage has resulted in serious safety concerns and compromised the dam’s integrity.

BC Hydro’s Right Abutment Seepage Control Upgrade project — the most technically complex and highly constrained component of an overall $800-million dam and powerhouse upgrade — was undertaken to address the seepage issues and seismic performance.

As the main contractor, Golder’s work on the project included the development and application of a flexible mastic asphalt membrane to connect the dam with a new cut-off wall. This is the first known application of the technology in North America.

Golder’s role in the project included:

• The installation of overlapping jet grout columns to replace existing soils, and to strengthen the abutment underneath the concrete dam.

• Construction of a plastic concrete cut-off wall upstream and downstream of the dam using trench-cutter technology.

• Design and installation of a unique flexible membrane to connect the cut-off wall with the concrete dam. This previously untried and untested means of flexible connectivity was successfully achieved.

Creating the flexible membrane tie-in

The flexible membrane tie-in connection was the most challenging aspect of the project. The flexibility specification was developed by BC Hydro to meet the requirements of a 1-in-500 seismic event. In the case of an earthquake, the flexible membrane will allow for movement of the right abutment.

Golder proposed bitumen-based mastic asphalt for the flexible membrane. To create a space into which the membrane could be poured, a perfectly straight slot 25-m deep, nominally 168-mm wide, and 7 metres long was drilled through three different construction materials: plastic concrete, jet grout columns and concrete dam (see graphic). The membrane also had to be keyed into the bedrock.

During a lengthy pre-construction planning phase, which included finite element modelling, innovative solutions were adopted to address the challenges. This work involved:

• Developing a highly accurate, low-impact drilling technique to prevent deviation out of the dam, while maintaining dam stability.

• Completing final-stage drilling with the slot filled with water to maintain stability, ensuring dam safety.

• Completing a rigorous 15-month testing and trial program (including laboratory testing, batch-scale tests and field trials) for the mastic asphalt flexible membrane.

• Developing an installation method to ensure optimal membrane performance.

• Heating the water in the slot with a steam system to limit thermal losses and ensure mastic asphalt flow.

• Implementing unique real-time verification controls to build client confidence that the flexible membrane was free from defects and would meet flexibility and permeability requirements. The first attempt at membrane installation had to be successful, because once the mastic was installed and cooled it could not be removed.

Managing construction and protecting sensitive water bodies

The site had spatial and access restrictions which had to be managed, along with other challenges such as variable ground conditions.

Coordinating and scheduling the work, maintaining safety at the dam, and environmental considerations were also involved. The challenges led BC Hydro to initiate an “early contractor involvement” (ECI) process for its contract with Golder. This approach set a precedent for BC Hydro and resulted in the exchange of innovative ideas between BC Hydro and Golder throughout the planning and construction process. The work was completed within budget and on schedule.

Reducing the impacts of construction on the local community, as well as on the many recreational users of the Stave and Ruskin area, was important throughout the 17-month project. In keeping with BC Hydro’s commitment, where possible Golder used locally sourced materials, labour and services.

Golder prepared a comprehensive environmental protection plan that identified ways to mitigate the environmental impacts. Any uncontrolled release of materials from construction activities could affect a drinking water reservoir and the Stave River, a significant spawning and rearing habitat for salmon and trout. Throughout the construction environmental guidelines were followed, and work involving large quantities of potentially deleterious materials was able to be completed very close to these sensitive water bodies without incident.

The seismic improvements at the site will protect downstream inhabitants in the event of a 1-in-500 year seismic event. And once completed, the upgraded dam will produce enough electricity to serve more than 33,000 homes in B.C.’s Lower Mainland.

Project name: Ruskin Dam, Right Abutment Seepage Control Upgrade, Mission, B.C.

Award-winning firm (main contractor): Golder Associates

(Herb Hawson, P.Eng., Katherine McCann, Kevin Hachmeister,

Philip Birett, Megan Atkinson, P.Eng., Tasia Balding)

Owner-client: BC Hydro

Other key players: Foundex Explorations (drilling)