Boundary Dam Integrated Carbon Capture Storage – Award of Excellence

December 2, 2016

By Stantec

Jury Comments: “Another “first,” this project is a global leader — the first in the world to capture post-combustion carbon from an existing coal-fired power plant at a large commercial scale. It extends the life of the existing plant by 30 years and has the potential to keep coal as an energy option for the future. The challenges of integrating the systems into the existing plant were of a huge magnitude.”

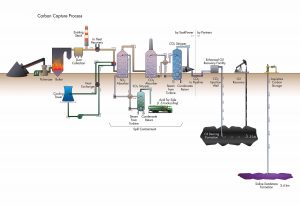

Overview of process at Boundary Dam Integrated Carbon Capture Storage project, Estevan, SK. Image: Stantec.

From the October-November 2016 print issue, p. 61.

SaskPower has achieved its ambitious plan of building the world’s first and largest commercial-scale integrated carbon capture and storage project on a coal-fired power plant.

Driven by pending environmental CO2 constraints and its aging generation assets, SaskPower selected an existing coal-fired plant, Boundary Dam Unit #3 (BD3) in Estevan, south Saskatchewan, to be retrofitted with a carbon capture system. The project has extended the life of the power plant by 30 years.

By capturing CO2 emissions from the coal-combustion process, the system helps to reduce the utility’s carbon footprint. It was designed to capture up to 1 million metric tonnes of carbon dioxide annually, equal to emissions from 250,000 cars. The carbon captured is then either sold for enhanced oil recovery purposes, or stored, permanently and safely 3.4 kilometres underground in a porous rock layer, sealed in by several layers of impermeable rock.

The project was complex due to: (a) the pioneering aspect of trying to achieve that which has never been done before; and (b) the sheer magnitude of the plant and system modifications that were needed.

Studies and design

As the owner’s engineer and prime consultant, Stantec’s work included studies of technologies, standards, etc., then support for the project’s design and construction.

Stantec provided services to:

• refurbish the BD3 boiler, replace the turbine/generator, and replace the associated mechanical, electrical, and instrumentation and controls for the balance of the plant.

• identify which BD3 components and systems required replacement or upgrade.

• reuse as much of BD3 as possible, while maintaining its reliability and safe operation.

• increase generation and overall plant efficiency wherever possible.

• support major technical EPC contracts; flue gas cooler, CO2 capture, CO2 compression balance of plant, heat rejection, and CO2 pipeline.

• integrate SO2 and CO2 capture processes.

• enable electrical generation to operate independently of the CO2 capture facility.

• reduce the SO2 emissions from the coal process by up to 99% and the CO2 emissions by up to 90%.

• demonstrate the economic, technical and environmental feasibility for coal-fired power generation with ICCS.

Innovation was paramount

Without reference projects, the project had many challenges requiring innovations and several “firsts.” To help with the design a detailed 3D CAD model derived by laser scanning the existing plant was generated and maintained to provide an accurate reference for the engineering team.

The project advances ICCS technologies and helps the global power industry reduce their greenhouse gas emissions. It has been recognized globally as a showcase for ICCS, including receiving the Edison Electric Institute 2015 Edison Award.

There are also significant social and economic benefits. For example, the construction required 4.5 million direct construction man-hours during the 41 month construction and commissioning period, which ended in 2014.

Boundary Dam Integrated Carbon Capture Storage,

Estevan, Sask.

Award-winning firm/prime consultant: Stantec , Regina, Sask. (David Cameron, P.Eng., Lucas Miller, P.Eng., Robert Swift, P.Eng., Jim Doolittle, P.Eng., Mike Richard, P.Eng., Shikhar Singh, P.Eng., Sandy Mackenzie, P.Eng., Randy Wedge, P.Eng., Gordon Boneschansker, P.Eng.)

Owner/client: Saskatchewan Power Corporation

Other key players: Clifton Associates (geotechnical); Midwest Surveys (survey)